Product Description

Call or Email For Pricing

*FREIGHT BILL WILL BE SENT SEPERATELY*

Specifications

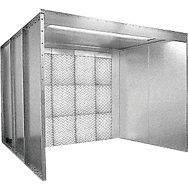

Interior Dimensions: 6'W x 8'H x 5'L

Exterior Dimensions: 6'4"W x 8'2"H x 7'8"L

Lights (qty): 1

Filters (qty): Blanket Exhaust Media

Fan Diameter: 24"

Fan Specs: 1.5 HP with 6,000 SCFM @ 1/2" SP

Shipping Weight: 1,020

Heavy duty construction

Batch and automated production designs

Easy to install

These floor model booths are designed for both batch type and line style production systems. Clean air is drawn in through the open front, across the parts being painted and exhausted through a filter bank in the rear of the booth. The fiberglass exhaust filters trap the airborne over spray particles before the filtered air is discharged through the exhaust duct system and into the atmosphere. The booths are available in a wide range of sizes and designs to meet practically any production requirements.

Conveyor slots can be as much as 25% of the booth open front area, without requiring an additional exhaust fan.

We can customize these spray booths to meet your requirements. Heated air replacement units and intake chambers can be added as well as reduce air flows for automatic spray operations.

Lighting features

LED lighting is constructed of 22-gauge steel powder coated white, and available in 4000 and 8000 lumens. LED lighting provides lower energy usage, longer life, truer color rendering, reduced maintenance costs and comes with a 5 year warranty. LED lights are ETL listed for US and Canada with Class 1 Division 2, Group A, B, C, D and Class 2 Division 2, Group F and G ratings.

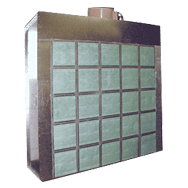

Exhaust system features

A tube-axial exhaust fan designed specifically for use in paint spray exhaust chambers powers the airflow through the booth and exhaust stack.

All exhaust fans have non-sparking blades. The motor drive and bearings are sealed from the air stream of the exhaust. Open drip proof motors are provided with each unit with a drive guard assembly.

Construction features and quality standards

Our Paint Booths are constructed from high quality 18-gauge galvanized steel. Structural steel is used to add strength and rigidity to chambers as necessary. All panels and support members are precision punched for easy nut and bolt installation. Panel flanges are connected externally to provide smooth internal surfaces.

All spray booth packages include detailed installation instructions, nuts, bolts, hardware and sealants necessary for assembly.

Optional UL/ ETL Listed Control Equipment:

A NEMA12 enclosure pre-wired and tested by RTT for simple hookup. Control panel includes main disconnect switch, class 10 motor protection, light contactor, fuse block, and field wiring terminal strip to easily connect interlock circuits such as door limit switches, light lens limit switch, air solenoid, and fire suppression. The class 10 motor protector offers maximum motor protection by being individually calibrated for the smallest and largest current it can handle and includes automatic ambient temperature compensation over a range of -13F to +140F.